Logistics & Supply Chain Applications

The distinct benefits offered by RFID technology enhance the effectiveness of transport, storage, production, and sales in the realm of supply chain management. With technological progress and cost reductions, it’s projected that the use of RFID technology will become increasingly widespread in managing supply chains.

- Home

- /

- RFID in Supply Chain and Logistics

Be

nefits of RFID in Supply Chain Management

- Highly adaptable to various environments with resistance to water, magnetism, and high temperatures.

- Provides long reading range coupled with quick command reading capabilities.

- Comes equipped with customizable password protection for enhanced security.

- Ensures prolonged data retention time for effective long-term use.

- The stored data can be frequently read and written by RFID warehouse inventory management, promoting reuse and efficiency.

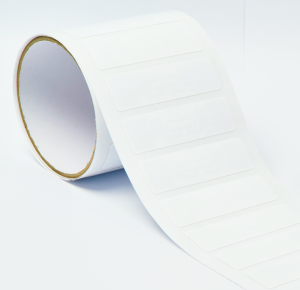

RFID Technology in Logistics Operations

By attaching RFID tags to products and vehicles and incorporating RFID label readers in the vehicles, every stakeholder – from suppliers to distributors and end customers – gains real-time access to the location, status, and estimated arrival of goods through the Internet. This approach, employing RFID tags for inventory control, mitigates the expenses associated with conventional GPS location tracking. The operational center’s GIS geographic analysis system also enables swift allocation and path optimization of cargo vehicles, leading to a better utilization rate of the vehicles.

RFID Technology in Warehouse Management

With the implementation of RFID tags on merchandise, each product possesses its own unique ID number. The RFID reader allows the warehouse supervisor to carry out an automated inventory check and simultaneously update the data to the management center. The incorporation of sophisticated forklift-mounted systems enables companies to automate and intellectualize inventory management, enhancing storage precision and space efficiency. As goods with RFID tags approach the warehouse entry point, their information is read by the RFID-based warehouse management system and forwarded to the data management system. The data center then calculates the position of the goods and sends the information to the forklift truck system to create inventory instructions, leading to the correct storage of goods. The same automated process applies when goods are leaving the warehouse.

RFID Technology in Manufacturing

The installation of RFID tags on items ranging from raw materials to components, semi-finished goods, and finished products allows manufacturers to effectively track, identify and monitor items in the production line automatically. This approach expedites the process of locating necessary raw materials and parts from a complex inventory, considerably reducing costs and minimizing error rates associated with human identification, while improving production line efficiency. Moreover, by utilizing RFID tags for tracking, manufacturers can identify the sources of product quality issues, enabling more effective quality control. RFID’s real-time monitoring technology also allows manufacturers to increase the efficiency of JIT production.