Manufacturing

- Home

- /

- Manufacturing

At JIA RFID, we specialize in manufacturing precision RFID cards and tags. With advanced technology, our experienced professionals produce cost-effective RFID products, tailored to diverse applications. As demand grows, we continuously expand our facilities, enhance our production capacity and innovate our technology. We are committed to delivering excellent service, updated products, and insightful market trends to our customers.

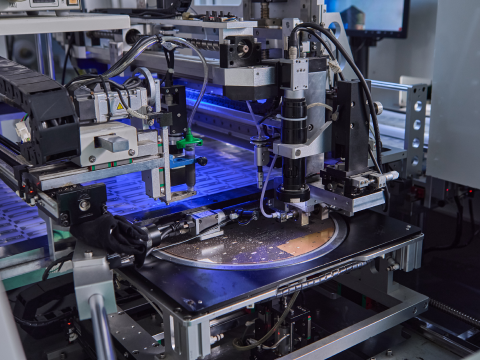

Utilizing Advanced Machinery for Enhanced RFID Production

At JIA RFID, we prioritize incorporating state-of-the-art machinery into our production processes. We have systematically upgraded our plant with the latest equipment designed specifically for developing and producing RFID cards and tags. These advanced machines and our comprehensive expertise enable us to manufacture exact and cost-effective RFID products. As a result, we can ensure superior quality control and enhanced production efficiency, fulfilling increased customer demands and keeping up with the rapid advancement of RFID technology.

Experienced Workforce: The Backbone of JIA RFID's Superior Manufacturing Proces

At JIA RFID, our dedicated and seasoned manufacturing team plays a vital role in our ability to deliver premium RFID products. Every member of our staff possesses specialized expertise in RFID technology, garnered from years of industry experience. This wealth of knowledge enables them to meticulously oversee each stage of production, ensuring the superior quality and reliability of our products. Our team’s unwavering commitment to precision and excellence is a testament to our reputation as a leading RFID manufacturer.

Efficient Manufacturing through Stringent Production Management

At JIA RFID, we operate under a stringent production management system that ensures the highest efficiency in our manufacturing processes. Our emphasis on strict quality control and time management has led us to consistently meet production deadlines without compromising the quality of our RFID products. Our rigorous protocols allow us to swiftly respond to the ever-increasing demand of our customers while constantly refining our manufacturing techniques. Our blend of advanced technology and meticulous production management fuels the growth of our company and guarantees customer satisfaction.

Auto Winding

Flip-chip encapsulation is a vital step in RFID production. In this process, the RFID chip is directly soldered onto a substrate with an antenna, then encased within a protective plastic shell. This technique offers higher integration and better performance, ensuring the stable operation of RFID tags under various conditions. The flip-chip encapsulation process can also enhance production efficiency and reduce manufacturing costs, making RFID devices more practical and economical.

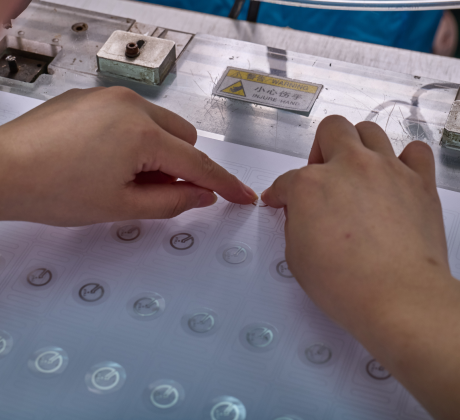

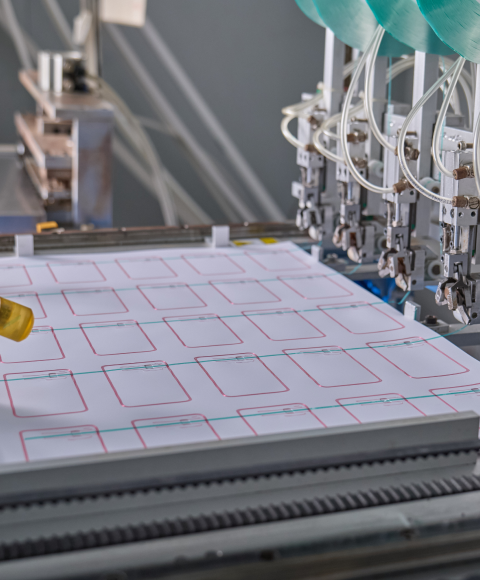

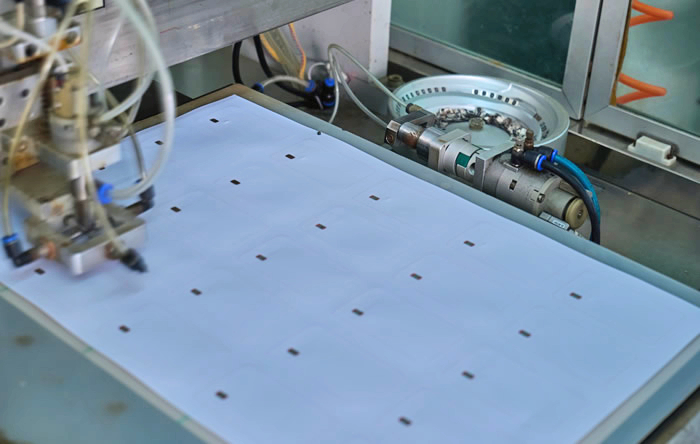

Stick Chip

Stick Chip process, a vital component of our manufacturing chain. This phase involves the precise placement and bonding of the RFID chip onto the antenna substrate, ensuring optimal signal transmission. Our skilled technicians employ advanced machinery to achieve this with remarkable accuracy. Each chip undergoes rigorous testing for quality assurance, meeting the high standards set by bulk purchasers and distributors. The “Stick Chip” process is a testament to our commitment to superior quality and performance in our RFID products. Experience the difference in consistency and reliability with our meticulously crafted RFID solutions, where precision and quality are paramount.

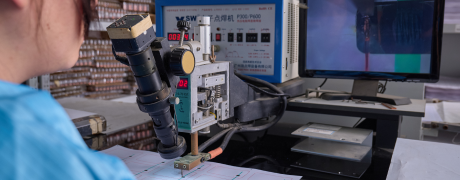

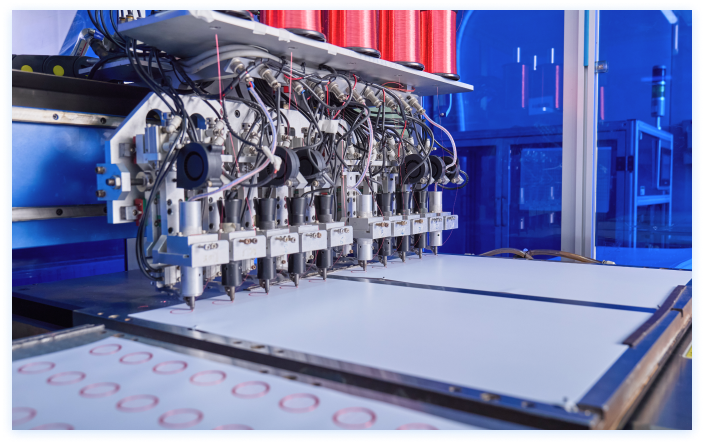

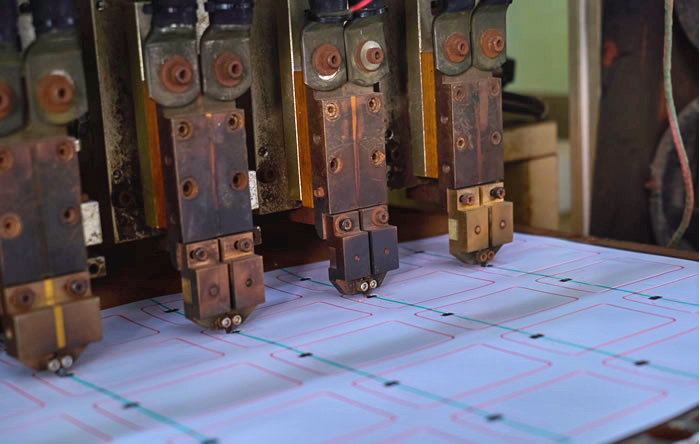

Auto Welding

Auto Welding process, this automated process ensures optimal electrical connections between the antenna and the chip, a crucial step in RFID & Prox Cards production. Our rigorous quality control measures are implemented at each stage, ensuring each weld is perfect and our products are of the highest quality. We utilize advanced technology and skilled technicians to oversee this process, guaranteeing consistency and reliability for our bulk purchasers and distributors. Our commitment to excellence in our Auto Welding process sets us apart in the RFID industry.

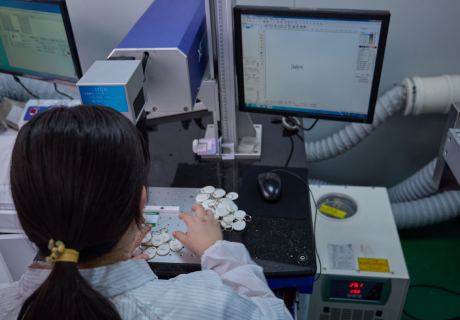

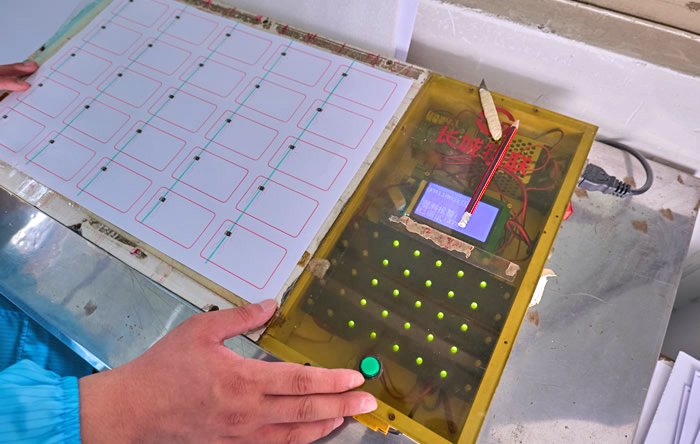

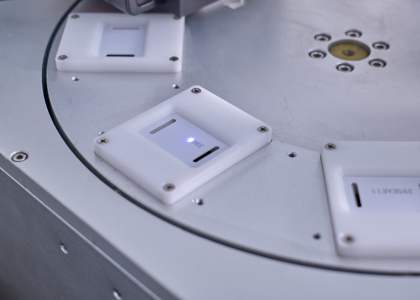

Testing

We believe that “Testing” is a cornerstone of our production process. Every RFID & Prox Card undergoes rigorous testing to ensure superior performance and durability. Our comprehensive testing procedures include functionality checks, frequency testing, and stress tests under various environmental conditions. We utilize advanced testing equipment and methodologies to ensure that each product meets our stringent quality standards. Our team of experienced technicians meticulously monitors this process, ensuring consistent quality and reliability for our bulk purchasers and distributors. This meticulous attention to detail in our Testing phase underscores our commitment to delivering high-quality RFID products in the industry.

Combination

Combination is a critical step that ensures the high quality and reliability of our products. This stage involves the precise assembly of the antenna and chip, where each component is carefully combined to form the integral structure of the RFID & Prox Cards. Our experienced technicians employ state-of-the-art equipment to guarantee the accurate alignment and secure attachment of these parts. This stringent process is closely monitored and subjected to rigorous quality checks, ensuring that each product we produce meets the highest standards of performance and durability. Our commitment to excellence in this crucial manufacturing phase is what sets us apart, making us the go-to choice for bulk buyers and distributors seeking top-notch RFID solutions.

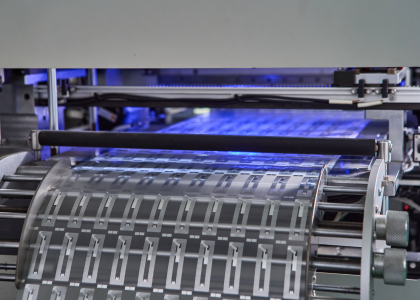

Inlay Lamination

In Inlay Lamination phase is pivotal in ensuring the durability and longevity of our RFID & Prox Cards. During Inlay Lamination, the assembled RFID inlay is encapsulated between layers of durable material, providing protection and enhancing the overall stability of the product. Our advanced lamination techniques and equipment ensure a seamless, secure encapsulation, preserving the integral components from environmental factors. Rigorous quality checks are conducted throughout this process, maintaining our commitment to delivering high-quality, robust RFID solutions. This dedication to excellence in our manufacturing process is why bulk buyers and distributors entrust us with their RFID requirements.

Made To Order

Vestibulum euismod nisl suscipit ligula volutpat, a feugiat urna maximus.

Custom: Limitless Possibilities

Vestibulum euismod nisl suscipit ligula volutpat, a feugiat urna maximus.

Understand Your needs

Vestibulum euismod nisl suscipit ligula volutpat, a feugiat urna maximus.